Disposable Cups

Our disposable cup range enables you to reduce the potential risk of cross contamination during uncertain times.

What about the environment?

Our disposable cup range can be recycled through recycling schemes. There are four recycling facilities asking for coffee cups. All have the ability to successfully separate the plastic from the paper which can then be recycled

Coffee-to-go

Early starters and the late nighters supporting the UK, we have on-the-go covered. Simply pour your hot beverage into any of our coffee-to-go range cups and off you go. The coffee-to-go cups can also be used with machines that have cups sensor technology.

Vending range

Our disposable vending cups have been specifically designed to be dispensed in vending and our range holds a variety of cups sizes to cater for different machines.

Are there any alternatives?

Our planet range is Biodegradable & Compostable.

Biodegradable is the breakdown of material by micro-organisms into invisible pieces, without turning into soil. In the presence of oxygen, the material converts to carbon dioxide, water, mineral salts and biomass. There are a number of facilities in the UK that can accept all manner of products.

Compostable means that packaging can break down in under 12 weeks in commercial composting conditions, and is therefore suitable for industrial composting.

What happens to my Recyclable Cups?

- The process starts with the product being placed in the recycling bin, when the user is finished with the item. This is then collected locally and sent to a recycling centre to be processed.

- The product is then unloaded onto a conveyor belt where it is sorted, normally by hand, removing any non-recyclable plastic and other items.

- The products are then sorted again, this time by colour.

- The sorted plastic is then shredded and reformed into pellets.

- The pellets are fed into a mould where they are used to create new products like plastic furniture or other packaging.

What happens to my Biodegradable Cups?

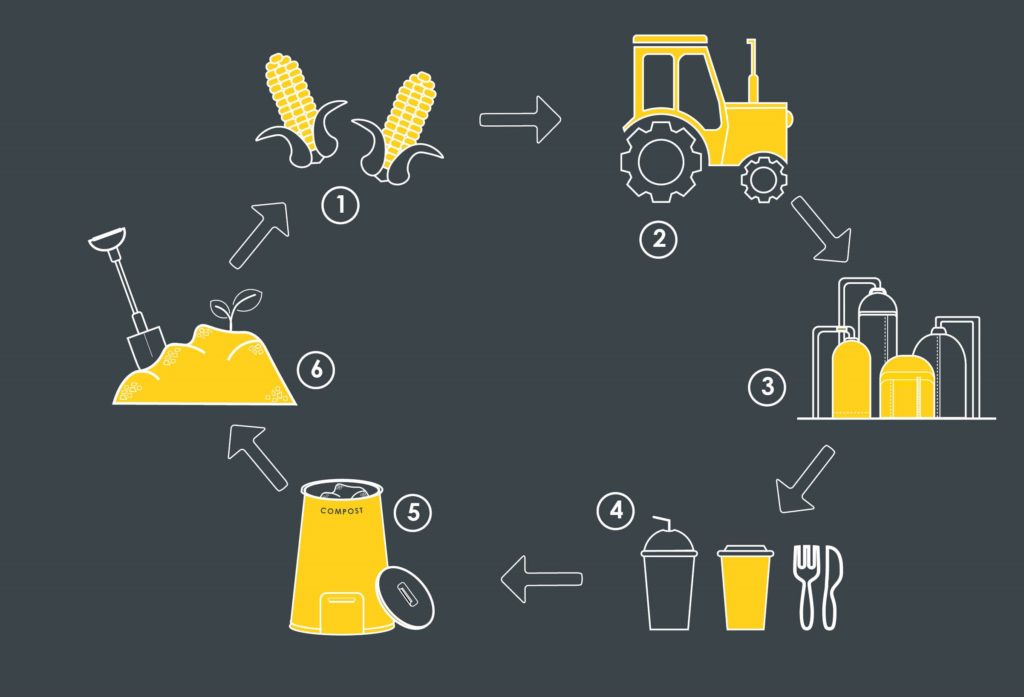

- The process starts with growing plants like corn, potatoes or sugar cane, anything with a high starch content, this is the material that replaces the petroleum.

- The plants are then harvested and processed to extract their starches.

- The starches are then processed further. This is done in bio-refinaries where special enzymes are added or fermentation takes place to produce chemical compounds that react to make plastics.

- The pellets of the starch compounds are used to make plastic cups or lining for paper cups as well as plates, utensils and other products. This product can now be used.

- When the user is finished with the product they can place their biodegradable product in an organic waste collection bin.

- The organic waste, when processed correctly, will compost and become mulch. This mulch when returned to the earth, can help new crops grow, completing the cycle and starting again.